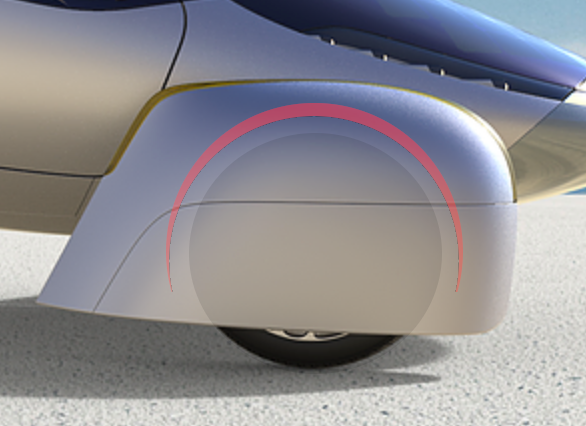

The heat transfer via the outer skin sounds sexy but also complex and expensive. The air circulation required for classic cooling is most likely to be found in the wheel arches. Built-in fenders in the two front wheel arches could function as a heat exchanger via a circuit with cooling liquid. If the existing air turbulence is not sufficient for cooling, an air flow can easily be built up via additional openings and fans, which supports the cooling (even when standing).

When I first read this wheel cooling idea, I thought it was interesting. I thought it could have similarities to the tunnel cooler on a snowmobile. Snow kicks up from the track and melts on an extruded aluminum heat exchanger to cool the engine. However, it doesn't cool the engine sufficiently if there is low snow. So the cooler has to be sized much larger to extract enough heat via air to liquid cooling. It's starting to sound big and heavy to me. You can't use a lightweight crossflow ICE radiator style cooler as it wouldn't stand up to stones and junk thrown up from the wheels.

I'm also less enthusiastic about an extruded aluminum cooler mounted on the front wheel pants. They would add to the unsprung weight problem.

However, Maybe it could be body mounted around the rear wheel only? Here again, it seems like not enough area around the rear wheel, but some math needs to be done to confirm this.

So I can now understand why Aptera wants to use skin cooling. Maybe they will have an aluminum belly pan with built in cooling tubes that also serves as battery mount and protection? Or maybe, they will adapt something from a cool suit, small capillary tubes taped on the inside of the body or belly pan with a small pump?

Another idea for better cooling of a surface (such as the back of the mudguards or the hubcaps) would be if it enlarges its surface depending on the temperature and thus enables more cooling. I am thinking here of small flaps that are arranged like scales and that stand up when heated. This can be solved easily and cheaply with a bimetal that presses the flap outwards (designed in such a way that the flap only opens when a certain temperature is reached).

For the outer skin that would of course also be a cool effect! Aptera reminds me a bit of a reptile anyway 😀

The cooling through the outer skin sounds sexy, as I said, and if that makes economic and technical sense, that's great! It would be interesting, however, which parts of the body are actually used. The doors and glass surfaces fail, surfaces on which solar cells are mounted should probably not be additionally heated either (since solar cells lose efficiency at higher temperatures - so they should be actively cooled).

If I understand correctly, we have two sources of heat: the in-wheel motors and the loader. In one case, heat is generated while driving, in the other while the vehicle is stationary.

I'm not a specialist in aerodynamics, but from projects with aerodynamically optimized bicycles I know that the protruding wheels are the Archilles' heel in fluid mechanics. There will be a lot of turbulence here that can be used for cooling and I think separate mudguards are necessary anyway, otherwise dirt will be deposited in the wheel arches.

Heat that arises during the charging process can possibly be dissipated directly on site via a separate ventilation system.

On the other hand, if the heat should also be used for heating, a circuit that integrates both sources is then required.

There won't be any traditional "brake" heat, but there will be some heat from regen braking.

Really only a wheel-sized disc in the outer part of the pants needs to be fairly easily removable for tire service.

Aptera will be cooling the in-wheel motors with a cooling loop going to a skin radiator in the body. With the brakes and motors both producing heat, you don't want any more heat sources in the wheel pants. The wheel pants need to be easily removable as well.

Yes, seems like a great idea! Maybe even just make all or part of the pants metal, & duct the coolant there. That should add less weight.

The hot part of any car or home A/C circuit heats only ambient air, not the interior.

None of the above list of heat sources gets very warm in my BEV, but the onboard charger sure does. That's by far the hottest part of my BEV, reaching about 140F on 6.6kW L2 even with liquid cooling. Hopefully Aptera's is more efficient, but even if they just go with 3.3kW that's half the heat.

On that note, interior-source-heat* dissipated through a mudguard in the REAR wheel arch might also be an idea to consider.

*Controllers, batteries, inverter, etc.

Hi Taubman. This seems like a very good idea. I agree with you that cooling might be an issue depending upon how many btu's we are dealing with. I like the idea of not having to connect the motors to the body, since they will be constantly articulating and stressing the hoses. Any minor flex such as that of flex hoses to the brakes eventually breaks them down. There certainly seems to be a large surface area given both inner and outer sides of the wheel fairings. If indeed it were not enough surface area to dissipate the heat, a small vertically aligned "radiator" could be placed either in front or behind the wheel/tire. Porsche did that with their trombone oil cooler which was placed in the right front wheel well and did not receive any directed airflow other than the turbulence to the spinning wheel/tire. I like the idea of not further heating the composite passenger shell with any further heat. It will need to deal with enough heat generated by the batteries, controller, inverter, DC-DC converter, and air-conditioning. For a car intended to be parked in the sun with minimal roll down side windows, count on the air conditioning to be on quite a bit in the southwestern portion of the US year-round.